TDF - TDC Corner Duct Corner Dies And Molds

TDF - TDC Corner Duct Corner Dies And Molds Specification

- Drive

- Manual

- Frame Type

- Fixed Mold Frame

- Noise Level

- Low

- Features

- Sturdy design, precision forming, corrosion-resistant finish

- Accuracy

- High (0.2 mm)

- Lubricating System

- Manual Lubrication Possible

- Operating Temperature

- Ambient

- Control System

- Manual

- Machine Type

- Duct Corner Mold

- Model No

- TDF-TDC-CDM-01

- Product Type

- TDF / TDC Corner Duct Corner Dies And Molds

- Technology

- Precision Steel Forming

- Power Source

- Manual

- Operating Type

- Manual

- Pressure

- Manual operation, no pressure required

- Surface Treatment

- Galvanized / Polished

- Dimension (L*W*H)

- 120mm x 75mm x 60mm

- Weight (kg)

- 3.5 kg (approx.)

- Color

- Silver / Metallic

- Production Capacity

- 75-120 pieces/day

- Usage & Applications

- Forming TDF or TDC duct corners in HVAC ductwork

- Maintenance

- Minimal; regular cleaning recommended

- Shape

- Rectangular corner forming

- Service Life

- Above 50,000 cycles

- Compatibility

- Suitable for TDF and TDC Duct Corners

- Export Markets

- Asia, Middle East, Africa

- Material

- High Carbon Steel / Alloy Steel

- Packaging Details

- Individual box packing

- Application Industry

- HVAC, Ventilation Duct Manufacturing

- Finish Type

- Rust-resistant finished surface

- Replacement Parts

- Available on request

- Installation

- Plug and play with standard forming presses

- Working Speed

- Operator Dependent

- Operator Skill

- Semi-skilled/Skilled

- Edge Type

- Smooth & Burr-free

- Tolerance

- ±0.2 mm

TDF - TDC Corner Duct Corner Dies And Molds Trade Information

- Minimum Order Quantity

- 1 , , Unit

- Supply Ability

- 1 , , Unit Per Day

- Delivery Time

- 13 Days

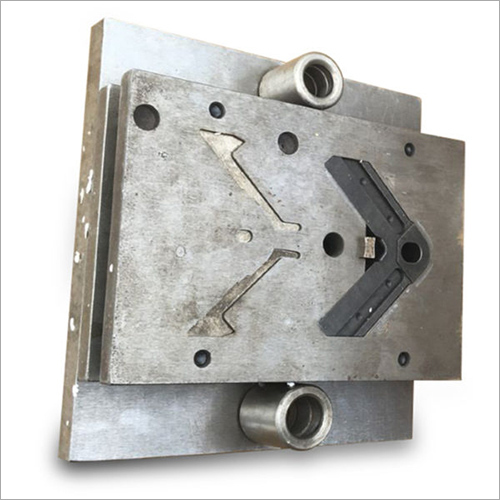

About TDF - TDC Corner Duct Corner Dies And Molds

{"","Being a well-renowned firm, we are presenting TDF - TDC Corner Duct Corner Dies And Molds of the best quality. These have high strength, super rust resistance, ideal dimension, durability, and give ideal shape and size with first-class to the duct corners. Effortless to fit to the industrial molding machine, these are precision designed and fabricated from the best grade steel metal with advanced casting technology. Further, clients can get TDF - TDC Corner Duct Corner Dies And Molds in varied dimensions at negotiable prices.

High Durability & Precision

Crafted using high carbon steel or alloy steel, these duct corner molds present robust performance and exceptional resistance to corrosion. Precision workmanship and a fixed mold frame ensure that each corner is formed with high accuracy and smooth, burr-free edges, contributing to efficient production workflows in HVAC manufacturing.

Plug-and-Play Installation for Seamless Setup

Designed for hassle-free integration, these dies and molds can be installed with standard forming presses without requiring specialized equipment or complex procedures. Their manual operation and straightforward dimensions make them accessible for semi-skilled and skilled workers alike.

FAQ's of TDF - TDC Corner Duct Corner Dies And Molds:

Q: How are TDF-TDC Corner Duct Corner Dies and Molds installed?

A: These molds feature a plug-and-play setup compatible with standard forming presses. Operators can quickly position and secure them, requiring no special tools or equipment for installation.Q: What are the primary usage and applications of this product?

A: They are primarily used for forming smooth, rectangular corners in TDF and TDC ductwork, mainly within the HVAC and ventilation industry, ensuring accurate and reliable duct construction.Q: What materials are used in manufacturing these molds?

A: The molds are constructed from high carbon steel or alloy steel, providing high strength, durability, and resistance to wear and corrosion in demanding environments.Q: When should replacement parts be considered, and how can they be obtained?

A: Replacement parts are recommended in case of excessive wear or damage after extensive use. They are available upon request from the distributor, manufacturer, or supplier.Q: Where can these molds be exported and supplied?

A: These molds are available for export and supply across Asia, the Middle East, and Africa, with distribution supported by authorized manufacturers and traders.Q: What maintenance is required for optimal performance?

A: Only minimal maintenance is needed; regular cleaning is recommended to maintain product accuracy and longevity. Manual lubrication can be performed if necessary.Q: What benefits does this mold offer during duct corner forming?

A: It ensures precise, burr-free edges, quick setup, high production capacity, and low noise operation, thus improving workflow efficiency and overall product quality.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in HVAC Duct Machine Category

Auto Duct Pipe Production Line 3 Duct Pipe Making Line III

Price Range 600.00 - 6000.00 USD ($) / Unit

Minimum Order Quantity : 1 , , Unit

Pressure : Standard atmospheric

Power Source : Other, Electric

Drive : AC Motor Drive

Frame Type : Heavyduty Steel Frame

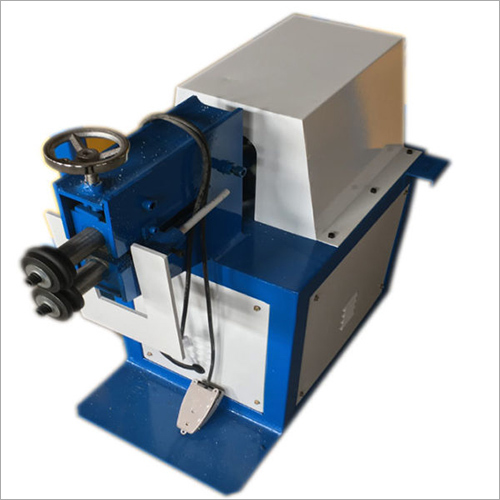

Groove Rotary And Duct Reviting Machine

Price Range 600.00 - 6000.00 USD ($) / Unit

Minimum Order Quantity : 1 , , Unit

Pressure : Adjustable via manual lever (specific value not provided)

Power Source : Other, Electric

Drive : Gear Drive

Frame Type : Fabricated Steel

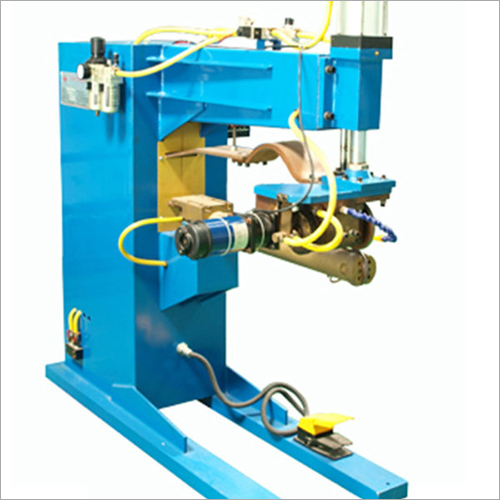

Air Duct Pipe Seam Welding Machine Duct Pipe Seam Welder Machine

Price Range 600.00 - 6000.00 USD ($) / Unit

Minimum Order Quantity : 1 Unit

Pressure : Adjustable, up to 0.8 MPa

Power Source : Other, Electric

Drive : Chain Drive

Frame Type : Heavy Duty Steel Frame

6 mm Automatic Angle Steel Punching And Cutting Machine With Flange Punching Line

Price Range 600.00 - 6000.00 USD ($) / Unit

Minimum Order Quantity : 1 Unit

Pressure : Up to 1000 kN

Power Source : Other, Electric

Drive : Servo & Hydraulic

Frame Type : Reinforced Welded Frame

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry