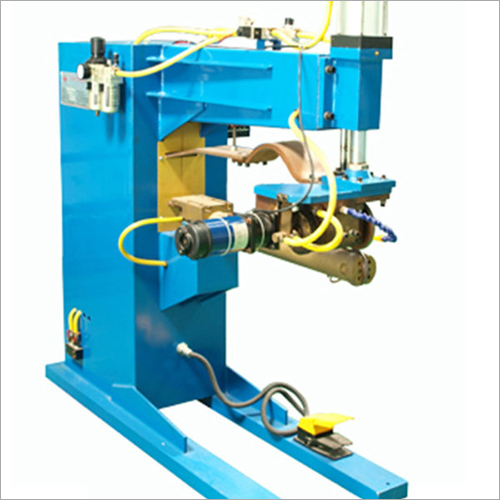

Air Duct Pipe Seam Welding Machine Duct Pipe Seam Welder Machine

Air Duct Pipe Seam Welding Machine Duct Pipe Seam Welder Machine Specification

- Model No

- ADS-1600

- Voltage

- 380V/415V

- Connectivity Options

- Standard Input/Output

- Frame Type

- Heavy Duty Steel Frame

- Features

- High precision, robust construction, energy efficient

- Power Rating

- 7.5 kW

- Cooling System

- Water Cooling

- Motor Power

- 1.5 kW

- Machine Type

- Seam Welder Machine

- Drive

- Chain Drive

- Noise Level

- 75 dB

- Lubricating System

- Centralized Lubrication

- Accuracy

- 0.5 mm

- Production Capacity

- 20-30 pieces/hour

- Operating Temperature

- 5 45

- Frequency

- 50/60 Hz

- Control System

- PLC Control

- Product Type

- Air Duct Pipe Seam Welding Machine

- Technology

- Resistance Welding

- Power Source

- Electric

- Operating Type

- Semi Automatic

- Power

- 7.5 kW

- Pressure

- Adjustable, up to 0.8 MPa

- Surface Treatment

- Powder Coated

- Dimension (L*W*H)

- 3200mm 1000mm 1800mm

- Weight (kg)

- 1200 kg

- Color

- Blue-Grey

- Usage & Applications

- For seam welding of round, square, and rectangular air duct pipes

- Welding Wheel Material

- Alloy Copper

- Operator Interface

- Touch Screen

- Electrical Protection

- Overload/Short-circuit Protection

- Compressed Air Requirement

- 0.5-0.8 MPa

- Max Pipe Diameter

- 1600 mm

- Min Pipe Diameter

- 100 mm

- Weldable Material Thickness

- 0.5 - 1.2 mm

- After-sales Service Provided

- Engineers available for overseas service

- Transport Package

- Wooden Crate

- Welding Length

- 300-3100 mm

- Welding Current Control

- Digital Adjustable

- Installation Type

- Floor Mounted

Air Duct Pipe Seam Welding Machine Duct Pipe Seam Welder Machine Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 1 Unit Per Day

- Delivery Time

- 13 Days

About Air Duct Pipe Seam Welding Machine Duct Pipe Seam Welder Machine

Versatile Applications, Premium Features

Engineered for seam welding of round, square, and rectangular air duct pipes, this machine suits HVAC, construction, and industrial production lines. Its surface applications span galvanized, coated, or stainless steel sheets, enhancing adaptability. The robust powder-coated exterior, centralized lubrication, and water cooling present peerless operational durability. A digital touch screen interface, PLC control, and supreme overload protection highlight its technological edge, while the heavy-duty steel frame ensures stability during demanding tasks.

Swift Delivery and Flexible Supply Policy

Goods are transported securely worldwide, shipped in sturdy wooden crates to preserve integrity. Delivery times depend on the order quantity and specifications, typically quoted upon inquiry to ensure transparency. As a leading exporter and manufacturer, we maintain reliable supply ability to meet bulk or urgent requirements. Sample policies are flexible; quotations for trial units or bulk orders are readily provided to support your project planning and evaluation needs efficiently.

Specifications:

| Item Type | FN-35 | FN-55 | FN-75 | FN-100 |

| Rated input capacity | 35KVA | 55KVA | 75KVA | 100KVA |

| Rated input voltage | 1-38V/50HZ | 1-38V/50HZ | 1-38V/50HZ | 3-38V/50HZ |

| Rated load cycle | 50% | 50% | 50% | 50% |

| Max.input capacity | 45KVA | 55KVA | 75KVA | 110KVA |

| Max.short circuit current | 6200A | 11000A | 16000A | 26000A |

| Max.pressure of electrode | 400KGF | 600KGF | 1000KGF | 1000KGF |

| The flow of cooling water | 6L/min | 6L/min | 8L/min | 8L/min |

| Arm length | 600mm | 600mm | 600mm | 600mm |

| Electrode journey | 80mm | 80mm | 80mm | 80mm |

| Speed of welding | 0.5-3m/min | 0.5-3m/min | 0.5-3m/min | 0.5-3m/min |

| Weight | 328kg | 378kg | 428kg | 478kg |

FAQs of Air Duct Pipe Seam Welding Machine Duct Pipe Seam Welder Machine:

Q: How does the welding process ensure accuracy and quality on various duct pipe shapes?

A: The machine uses a PLC control system paired with digital welding current adjustment and alloy copper welding wheels, delivering consistent, high-quality seams on round, square, and rectangular duct pipes with an accuracy of 0.5 mm.Q: What types of materials and pipe dimensions can be welded with this machine?

A: This seam welder accommodates duct pipes with diameters from 100 mm to 1600 mm and weldable material thickness between 0.51.2 mm, including galvanized, coated, or stainless steel classed sheets.Q: When can I expect my order to be shipped and delivered?

A: Delivery times vary based on order size and custom requirements. Exact timelines are provided in your quotation, and goods are shipped worldwide in protective wooden crates to ensure safe arrival.Q: Where is this machine most commonly used?

A: The Air Duct Pipe Seam Welding Machine is widely used in HVAC duct manufacturing, construction, ventilation systems fabrication, and industrial air distribution applications.Q: What are the benefits of the machines cooling and lubrication systems?

A: Centralized lubrication and water cooling systems significantly extend service life, reduce wear on components, and enable prolonged high-volume operation with stable weld quality.Q: How is the after-sales service provided for overseas clients?

A: Engineers are available for overseas service, offering installation, training, and maintenance support, ensuring seamless operation and quick troubleshooting wherever clients are located.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in HVAC Duct Machine Category

Auto Square Duct Production Line 2 Pipe Tube Making Machine

Price Range 600.00 - 6000.00 USD ($) / Unit

Minimum Order Quantity : 1 , , Unit

Accuracy : 0.5 mm

Technology : Other, Fully Automatic Roll Forming

Production Capacity : 612 m/min (Line speed)

Operating Temperature : 5C ~ 40C

Auto Duct Manufacture Line 6 Duct Make Line U Shape

Price Range 600.00 - 6000.00 USD ($) / Unit

Minimum Order Quantity : 1 , , Unit

Accuracy : 0.5 mm

Technology : Other, CNC Automation

Production Capacity : 1625 m/min

Operating Temperature : 5C 40C

6 mm Automatic Angle Steel Punching And Cutting Machine With Flange Punching Line

Price Range 600.00 - 6000.00 USD ($) / Unit

Minimum Order Quantity : 1 Unit

Accuracy : 0.5 mm

Technology : Other, CNC Automation

Production Capacity : 20002500 pieces/day

Operating Temperature : 10C to 45C

Air Duct Pipe Double Tdf Flange Machine Doublex Tdf Flange Forming Machine

Price Range 600.00 - 6000.00 USD ($) / Unit

Minimum Order Quantity : 1 Unit

Accuracy : 0.5 mm

Technology : Other, Coldforming / Roll forming

Production Capacity : 812 meters/minute

Operating Temperature : 5C to 40C

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry