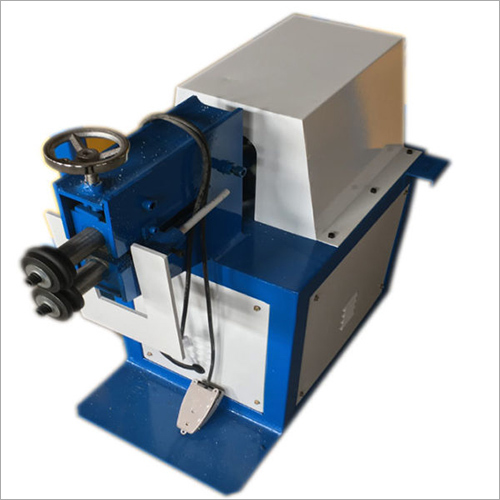

Groove Rotary And Duct Reviting Machine

Groove Rotary And Duct Reviting Machine Specification

- Machine Type

- Rotary and Riveting

- Model No

- GRM-100

- Frequency

- 50/60 Hz

- Operating Temperature

- 0C - 45C

- Features

- Heavy-duty frame; High precision grooving; Energy efficient operation

- Connectivity Options

- Basic electrical input

- Cooling System

- Air-cooled

- Control System

- Panel Operated

- Production Capacity

- 80-100 ducts/hour

- Power Rating

- 0.75 kW

- Accuracy

- 0.2 mm

- Frame Type

- Fabricated Steel

- Lubricating System

- Manual Lubrication

- Motor Power

- 0.75 kW

- Noise Level

- <85 dB

- Drive

- Gear Drive

- Voltage

- 220V / 380V AC

- Product Type

- Groove Rotary and Duct Reviting Machine

- Technology

- Rotary Riveting Technology

- Power Source

- Electric

- Operating Type

- Semi-Automatic

- Power

- 0.75 kW

- Pressure

- Adjustable via manual lever (specific value not provided)

- Surface Treatment

- Powder Coated

- Dimension (L*W*H)

- 1200 mm x 650 mm x 1000 mm

- Weight (kg)

- 180 kg

- Color

- Industrial Grey

- Usage & Applications

- Grooving and riveting duct panels in HVAC, sheet metal and fabrication industries

- Installation Type

- Floor Mounted

- Standard Accessories

- Rivet Setters, Grooving Rollers

- Service Support

- On-site and Remote Technical Assistance

- Grooving Thickness Range

- 0.5 mm to 1.5 mm

- Packaging

- Wooden crate

- Power Consumption

- 0.8 kWh

- Main Shaft Diameter

- 45 mm

- Shield Type

- Transparent Operator Shield

- Safety Features

- Emergency Stop, Overload Protection

- Input Material

- Mild Steel, Galvanized Sheet

- Spindle Speed

- 1200 rpm

- Rivet Type

- Solid and Hollow

- Ambient Humidity

- Max 85% RH

- Tool Change System

- Manual

- Time for Riveting

- 2-3 seconds per point

- Rivet Diameter Range

- 2 mm to 4 mm

- Roller Material

- Hardened Tool Steel

Groove Rotary And Duct Reviting Machine Trade Information

- Minimum Order Quantity

- 1 , , Unit

- Supply Ability

- 1 , , Unit Per Day

- Delivery Time

- 13 Days

About Groove Rotary And Duct Reviting Machine

{"","Groove Rotary And Duct Reviting Machine we bring forth is extensively utilized in HVAC duct fabrication system industry, especially for flanging as well as beading with specific rollers. Plus, it can also make the various workpieces with particular rolling wheels, like for shearing sheets, leveling metal sheets, corrugating plates, and so on. Groove Rotary And Duct Reviting Machine is equipped with 3 sets moulds for flanging comprising the Swaging machine.

Specifications:

| Model | Max Thickness (mm) | Motor(kw) | Weight(kg) | Size(mm) |

| LX-15 | 1.2 | 0.75 | 120 | 820x520x900 |

Precision Grooving and Riveting

Achieve seamless joints and consistent quality with the Groove Rotary and Duct Riveting Machine. High accuracy (0.2 mm) and rapid operation (1200 rpm spindle speed) guarantee uniform grooving and robust riveting for HVAC and sheet metal ducts. Its hardened tool steel rollers enhance durability, while adjustable pressure ensures optimal results for a variety of panel thicknesses.

Built for Safety and Operator Comfort

Operator safety remains paramount, with features including a transparent protective shield, emergency stop buttons, and overload protection. These safeguards, combined with a user-friendly panel-operated control system, empower operators to maintain high productivity with peace of mind.

Flexible and Robust Performance

Supporting a wide rivet diameter range (2 mm to 4 mm) and accepting both solid and hollow rivets, the machine efficiently processes duct panels using mild steel or galvanized sheet inputs. Manual tool change and pressure adjustment systems provide flexibility, while its floor-mounted, heavy-duty frame assures stability even during high-volume production.

FAQ's of Groove Rotary And Duct Reviting Machine:

Q: How does the Groove Rotary and Duct Riveting Machine ensure safety during operation?

A: The machine features comprehensive safety measures, including an emergency stop button, overload protection, and a transparent operator shield. These components protect users from accidental contact and operational hazards, helping to maintain a secure working environment.Q: What materials and rivet types can be used with this machine?

A: This machine is compatible with mild steel and galvanized sheet panels. It supports both solid and hollow rivets, accommodating diameters from 2 mm to 4 mm, which offers versatility for various duct fabrication needs.Q: When should I perform tool changes on the machine, and how is it done?

A: Tool changes should be performed when switching between different grooving rollers or rivet sizes, or when wear is observed on existing components. The system employs a manual tool change mechanism for efficient and straightforward replacement, ensuring minimal downtime.Q: Where is the ideal location for installing this machine?

A: The machine is designed for floor-mounted installation in industrial settings such as HVAC fabrication shops or sheet metal workshops. A stable, level floor near standard electrical outlets (220V/380V AC) is recommended for optimal performance and safety.Q: What is the process for grooving and riveting with this machine?

A: Panel sheets are guided between grooving rollers to create precise grooves, followed by semi-automatic riveting accomplished in 2-3 seconds per point. The spindle operates at 1200 rpm for efficient throughput, while pressure can be manually adjusted for different panel thicknesses.Q: How much production capacity can I expect?

A: The machine is capable of producing 80 to 100 ducts per hour, depending on material size and operator efficiency, making it ideal for large-scale duct and panel fabrication projects.Q: What are the primary benefits of using the Groove Rotary and Duct Riveting Machine?

A: Key benefits include high production rates, precise and consistent results (0.2 mm accuracy), energy-efficient operation (0.8 kWh consumption), and enhanced operator safety. Its robust construction and advanced features collectively ensure long service life and reduced operational costs.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in HVAC Duct Machine Category

Auto Duct Pipe Production Line 3 Duct Pipe Making Line III

Price Range 600.00 - 6000.00 USD ($) / Unit

Minimum Order Quantity : 1 , , Unit

Lubricating System : Automatic Lubrication

Accuracy : 1 mm

Frame Type : Heavyduty Steel Frame

Dimension (L*W*H) : 12000 x 2200 x 1500 mm

Auto Square Duct Production Line 2 Pipe Tube Making Machine

Price Range 600.00 - 6000.00 USD ($) / Unit

Minimum Order Quantity : 1 , , Unit

Lubricating System : Automatic Lubrication

Accuracy : 0.5 mm

Frame Type : Heavy Duty Welded Steel Frame

Dimension (L*W*H) : 12000 mm 2100 mm 1500 mm (Approx.)

Auto Duct Manufacture Line 6 Duct Make Line U Shape

Price Range 600.00 - 6000.00 USD ($) / Unit

Minimum Order Quantity : 1 , , Unit

Lubricating System : Automatic

Accuracy : 0.5 mm

Frame Type : Heavy Duty Steel Frame

Dimension (L*W*H) : 24000 x 3300 x 1800 mm

6 mm Automatic Angle Steel Punching And Cutting Machine With Flange Punching Line

Price Range 600.00 - 6000.00 USD ($) / Unit

Minimum Order Quantity : 1 Unit

Lubricating System : Automatic Lubrication

Accuracy : 0.5 mm

Frame Type : Reinforced Welded Frame

Dimension (L*W*H) : 8500 mm x 2200 mm x 1800 mm

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry