6 mm Automatic Angle Steel Punching And Cutting Machine With Flange Punching Line

6 mm Automatic Angle Steel Punching And Cutting Machine With Flange Punching Line Specification

- Frame Type

- Reinforced Welded Frame

- Model No

- ASPC-6FPL

- Power Rating

- 18 kW

- Motor Power

- 7.5 kW

- Cooling System

- Industrial Water Cooling

- Accuracy

- 0.5 mm

- Voltage

- 380 V

- Lubricating System

- Automatic Lubrication

- Features

- High precision, integrated punching and cutting, automatic feeding, multi-hole punching capability

- Operating Temperature

- -10C to 45C

- Drive

- Servo & Hydraulic

- Connectivity Options

- USB, Ethernet

- Production Capacity

- 2000-2500 pieces/day

- Frequency

- 50 Hz

- Noise Level

- 70 dB

- Machine Type

- Flange Punching Line

- Control System

- PLC Control with Touchscreen

- Product Type

- Automatic Angle Steel Punching and Cutting Machine with Flange Punching Line

- Technology

- CNC Automation

- Power Source

- Electric

- Operating Type

- Automatic

- Power

- 18 kW

- Pressure

- Up to 1000 kN

- Surface Treatment

- Powder Coating

- Dimension (L*W*H)

- 8500 mm x 2200 mm x 1800 mm

- Weight (kg)

- 9500 kg

- Color

- Blue & White

- Usage & Applications

- Angle steel punching and cutting for transmission towers, steel structures, etc.

- Transport Package

- Export Wooden Case

- Min Angle Size

- 40 x 40 x 3 mm

- Working Language

- Multilingual (English, Chinese, etc.)

- After-Sales Service

- Online Support, Spare Parts Supply

- Cutting Type

- Single/Double Shear

- Hydraulic Oil Tank Capacity

- 300 L

- Punching Diameter Range

- Ø10-Ø32 mm

- Total Hydraulic Power

- 15 kW

- Control Interface

- Color Touchscreen (HMI)

- Automated Feeding Length

- Up to 12 meters

- Max Angle Size

- 160 x 160 x 16 mm

- Installation Service

- Available

- Max Punching Thickness

- 6 mm

- Material Type

- Carbon Steel, Stainless Steel

- Safety System

- Emergency Stops; Safety Interlocks

- Required Operator

- 1 Person

- Software Compatibility

- DXF, NC, LXD files

6 mm Automatic Angle Steel Punching And Cutting Machine With Flange Punching Line Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 1 Unit Per Day

- Delivery Time

- 13 Days

About 6 mm Automatic Angle Steel Punching And Cutting Machine With Flange Punching Line

Versatile Uses and Application Sites

The 6 mm Automatic Angle Steel Punching and Cutting Machine with Flange Punching Line is widely utilised in manufacturing transmission towers, steel structural fabrications, and workshop metal processing. It's also deployed in railway construction, power grid frameworks, and construction scaffolding. Used as a high-performance, single-operator solution, this premier system is ideal for any site demanding efficient, precise angle steel punching and cutting for both domestic and export projects.

Packaging, Market, and Sample Exchange Policy

Each machine is securely shipped in an export-standard wooden case, ensuring safe handover and easy transportation anywhere. Main domestic markets include industrial hubs and construction zones, with robust export support to global destinations. A sample policy is available if you require trial models before final procurement. Our steadfast exchange and after-sales support promote seamless installation and maintenance, delivering continual value to clients worldwide.

FAQ's of 6 mm Automatic Angle Steel Punching And Cutting Machine With Flange Punching Line:

Q: How does the automatic feeding system enhance productivity?

A: The automated feeding system allows continuous processing of angle steel up to 12 meters in length, reducing manual labor and minimizing downtime, which significantly boosts production rates.Q: What are the main benefits of using this Virtuoso punching and cutting machine?

A: The main benefits include exceptional accuracy (0.5 mm), high speed, multi-hole and flange punching capability, single or double shear cutting, and a user-friendly touchscreen interface for efficient and reliable operation.Q: Where can the ASPC-6FPL be applied apart from transmission towers?

A: This premier machine is also ideal for fabricating steel structures, railway infrastructure, scaffolding, and various industrial assembly applications that require precise angle steel processing.Q: What process does the after-sales support follow?

A: After-sales support includes online guidance, spare parts supply, and, if necessary, on-site installation and maintenance to ensure optimal machine performance and client satisfaction.Q: How is secure shipping and installation ensured for overseas buyers?

A: The machine is delivered in a reinforced export wooden case for safe shipping. Professional installation services-including exchange and handover protocols-are available to guarantee a smooth setup at your facility.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in HVAC Duct Machine Category

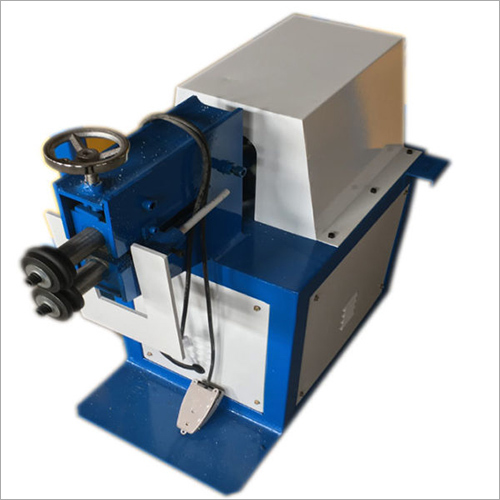

Groove Rotary And Duct Reviting Machine

Price Range 600.00 - 6000.00 USD ($) / Unit

Minimum Order Quantity : 1 , , Unit

Dimension (L*W*H) : 1200 mm x 650 mm x 1000 mm

Surface Treatment : Other, Powder Coated

Usage & Applications : Grooving and riveting duct panels in HVAC, sheet metal and fabrication industries

Technology : Other, Rotary Riveting Technology

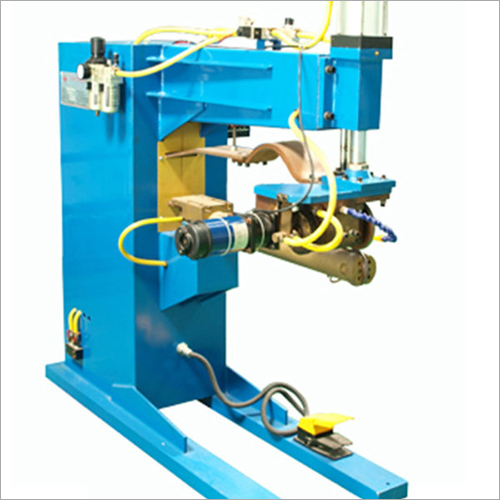

Air Duct Pipe Seam Welding Machine Duct Pipe Seam Welder Machine

Price Range 600.00 - 6000.00 USD ($) / Unit

Minimum Order Quantity : 1 Unit

Dimension (L*W*H) : 3200mm 1000mm 1800mm

Surface Treatment : Other, Powder Coated

Usage & Applications : For seam welding of round, square, and rectangular air duct pipes

Technology : Other, Resistance Welding

Auto Duct Manufacture Line 6 Duct Make Line U Shape

Price Range 600.00 - 6000.00 USD ($) / Unit

Minimum Order Quantity : 1 , , Unit

Dimension (L*W*H) : 24000 x 3300 x 1800 mm

Surface Treatment : Other, Powder Coated

Usage & Applications : HVAC Ductwork Manufacturing

Technology : Other, CNC Automation

Air Duct C&s Type Pittsburgh Lock Former Machine Duct Pipe Lock Forming Machine

Price Range 600.00 - 6000.00 USD ($) / Unit

Minimum Order Quantity : 1 Unit

Dimension (L*W*H) : 1450x650x1150 mm

Surface Treatment : Other, Painted/Coated

Usage & Applications : Sheet metal duct manufacturing; air duct forming

Technology : Other, Pittsburgh Lock Forming

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry