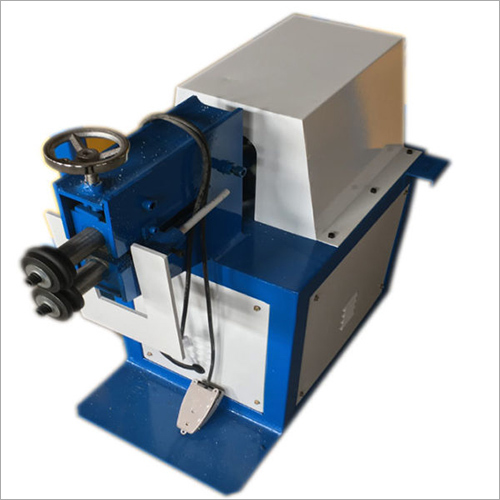

Electric Duct Locking and Zipping Machine

Electric Duct Locking and Zipping Machine Specification

- Voltage

- 220V / 380V

- Production Capacity

- 10-15 meters/min

- Motor Power

- 1.5 HP

- Power Rating

- 1.5 kW

- Operating Temperature

- 0C to 50C

- Cooling System

- Air cooled

- Features

- Heavy-duty construction, adjustable settings, low maintenance

- Machine Type

- Lock Forming/Zipping Machine

- Model No

- DLZ-1200

- Drive

- Chain Drive

- Frequency

- 50Hz / 60Hz

- Accuracy

- 1 mm

- Noise Level

- 75 dB

- Control System

- Button Control

- Lubricating System

- Automatic Lubrication

- Frame Type

- Rigid Welded Frame

- Product Type

- Duct Locking and Zipping Machine

- Technology

- Roll Forming/Zipping Technology

- Power Source

- Electric

- Operating Type

- Automatic/Semi-Automatic

- Power

- 1.5 kW

- Pressure

- Standard shop air pressure (as required for duct forming)

- Surface Treatment

- Powder Coated

- Dimension (L*W*H)

- 1200 mm x 600 mm x 1100 mm

- Weight (kg)

- 250 kg

- Color

- Blue/Grey

- Usage & Applications

- Locking and sealing of ductwork in HVAC applications

- Thickness of Duct Material

- 0.5 mm - 1.2 mm

- Maximum Sheet Width

- 1250 mm

- After Sales Service

- Provided

- Motor Type

- Induction Electric Motor

- Maintenance Requirement

- Minimal

- Operator Requirement

- Single Operator

- Safety Features

- Overload protection, emergency stop button

- Transportation Wheels

- Included

- Minimum Sheet Width

- 150 mm

- Working Speed

- 10-15 m/min

- Roller Material

- Hardened Steel

- Setup Time

- <10 minutes

- Spare Parts Availability

- Ready Stock

- Working Width

- 1250 mm max

- Duct Shape Compatibility

- Rectangular and Round Ducts

Electric Duct Locking and Zipping Machine Trade Information

- Minimum Order Quantity

- 1 , , Unit

- Supply Ability

- 1 , , Unit Per Day

- Delivery Time

- 13 Days

About Electric Duct Locking and Zipping Machine

{"","Efficient and Versatile Duct Sealing

The DLZ-1200 Electric Duct Locking and Zipping Machine streamlines the process of locking and sealing HVAC ductwork. Compatible with both rectangular and round ducts, it supports various sheet thicknesses and widths up to 1250 mm, making it adaptable for diverse duct fabrication projects. Its roll forming and zipping technology ensures a strong, airtight seam-critical for effective ventilation systems.

User-Friendly Operation and Quick Setup

This machine is designed for ease of use, requiring only a single operator and less than 10 minutes for setup. Its button control system and semi/automatic functions simplify operation, while features like overload protection and emergency stop button ensure safety. The electric induction motor delivers steady power and efficiency during use.

Durable Build with Minimal Maintenance

Constructed from high-quality, powder-coated materials and featuring a hardened steel roller, the DLZ-1200 offers long-lasting durability. Its automatic lubrication system and air-cooled design reduce maintenance needs to a minimum, while spare parts are readily available, ensuring minimal downtime and reliable after-sales service.

FAQ's of Electric Duct Locking and Zipping Machine:

Q: How do I operate the Electric Duct Locking and Zipping Machine?

A: Operation is straightforward using the button control system. Once the machine is set up (typically in under 10 minutes), feed the duct sheet (rectangular or round) into the entry slot. Select desired settings for thickness and width, start the process, and the machine will automatically form and seal the ductwork at speeds of 10-15 meters per minute.Q: What types and sizes of ducts can this machine work with?

A: The DLZ-1200 is compatible with both rectangular and round duct shapes. It supports sheet material thickness from 0.5 mm to 1.2 mm and can process sheets with widths ranging from 150 mm up to a maximum of 1250 mm, making it suitable for most standard HVAC ductwork applications.Q: Where can this machine be installed, and does it require special facilities?

A: The DLZ-1200 is suitable for installation in standard shop environments and requires an electrical connection (220V or 380V, 50/60Hz) and shop air pressure for duct forming. Transportation wheels are included for easy relocation within the workshop. Its compact size allows integration into most duct fabrication setups.Q: What safety features are included in the machine?

A: For safe operation, the machine includes overload protection and an emergency stop button. The rigid welded frame and powder-coated surface also contribute to operator safety and equipment longevity.Q: How much maintenance does the DLZ-1200 require?

A: The machine is designed for low maintenance due to its automatic lubrication, air cooling, and high-quality components. Periodic checks are recommended for optimal performance, but minimal downtime is expected, supported by ready stock of spare parts and responsive after-sales service.Q: What are the main benefits of using this machine in HVAC duct fabrication?

A: Key advantages include high production capacity (10-15 meters/minute), precise 1 mm accuracy, fast setup, adaptability for various duct sizes, and robust safety and durability features. This improves overall efficiency and reliability for ductwork assembly.Q: Who can operate this machine, and is special training needed?

A: Only a single operator is needed, and since controls are straightforward, basic mechanical knowledge is sufficient. Manufacturer or distributor support is available for initial setup and operational guidance if required.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in HVAC Duct Machine Category

Auto Square Duct Production Line 2 Pipe Tube Making Machine

Price Range 600.00 - 6000.00 USD ($) / Unit

Minimum Order Quantity : 1 , , Unit

Production Capacity : 612 m/min (Line speed)

Operating Temperature : 5C ~ 40C

Machine Type : Duct Forming Machine

Features : High automation, quick changeover, servo feeder, integrated punching and shearing system

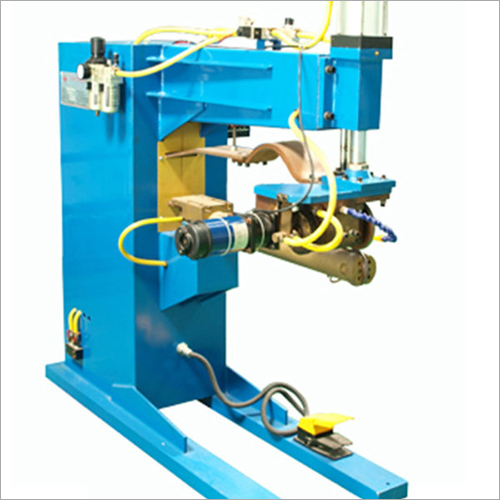

Air Duct Pipe Seam Welding Machine Duct Pipe Seam Welder Machine

Price Range 600.00 - 6000.00 USD ($) / Unit

Minimum Order Quantity : 1 Unit

Production Capacity : 2030 pieces/hour

Operating Temperature : 5 45

Machine Type : Seam Welder Machine

Features : High precision, robust construction, energy efficient

Groove Rotary And Duct Reviting Machine

Price Range 600.00 - 6000.00 USD ($) / Unit

Minimum Order Quantity : 1 , , Unit

Production Capacity : 80100 ducts/hour

Operating Temperature : 0C 45C

Machine Type : Rotary and Riveting

Features : Heavyduty frame; High precision grooving; Energy efficient operation

Auto Duct Manufacture Line 6 Duct Make Line U Shape

Price Range 600.00 - 6000.00 USD ($) / Unit

Minimum Order Quantity : 1 , , Unit

Production Capacity : 1625 m/min

Operating Temperature : 5C 40C

Machine Type : Duct Line U Shape

Features : Auto Feeding, Shearing, Notching, Bending, Grooving, Riveting

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry