Auto Square Duct Production Line 2 Pipe Tube Making Machine

Auto Square Duct Production Line 2 Pipe Tube Making Machine Specification

- Connectivity Options

- Standard (Ethernet/USB for program update)

- Power Rating

- 15 kW

- Voltage

- 380V/415V 3 Phase

- Drive

- Chain/gear drive system

- Model No

- Line 2

- Lubricating System

- Automatic Lubrication

- Frequency

- 50/60 Hz

- Operating Temperature

- 5C ~ 40C

- Control System

- PLC Touch Screen (Siemens/Omron)

- Production Capacity

- 6-12 m/min (Line speed)

- Plastic Processed

- N/A (Carbon steel/Galvanized Steel/Aluminum sheet applicable)

- Machine Type

- Duct Forming Machine

- Motor Power

- 11 kW Main Motor

- Frame Type

- Heavy Duty Welded Steel Frame

- Cooling System

- Air Cooled

- Noise Level

- 75 dB(A)

- Features

- High automation, quick changeover, servo feeder, integrated punching and shearing system

- Accuracy

- 0.5 mm

- Product Type

- Auto Square Duct Production Line 2 Pipe Tube Making Machine

- Technology

- Fully Automatic Roll Forming

- Power Source

- Electric

- Operating Type

- Automatic

- Power

- Approx. 15 kW

- Pressure

- 0.6 MPa (Air pressure required for pneumatic system)

- Surface Treatment

- Painted/Coated

- Dimension (L*W*H)

- 12000 mm 2100 mm 1500 mm (Approx.)

- Weight (kg)

- 6600 kg (Approx.)

- Color

- Blue/Gray

- Usage & Applications

- Making square and rectangular air duct pipes for HVAC, industrial ventilation, and building services

- Main Motor Brand

- Siemens/ABB Equivalent

- Maximum Duct Width

- 1250 mm

- Shearing System

- Hydraulic Servo Flying Shear

- Safety Features

- Emergency stop, interlock guards, fault alarms

- Operator Interface

- Human Machine Interface (HMI) with multilingual support

- Number of Stations

- Up to 16 rollers

- Material Thickness Range

- 0.5 1.2 mm

- Rollers Material

- High-grade, heat-treated steel

- Decoiler Type

- Automatic Hydraulic Decoiler

- Suitable Material Width

- 100 1250 mm

- Punching Type

- Servo controlled punching with interchangeable dies

- CNC Integration

- Yes, with data upload capability

- Minimum Duct Width

- 150 mm

- Electric Cabinet Protection

- IP54

Auto Square Duct Production Line 2 Pipe Tube Making Machine Trade Information

- Minimum Order Quantity

- 1 , , Unit

- Supply Ability

- 1 , , Unit Per Day

- Delivery Time

- 13 Days

About Auto Square Duct Production Line 2 Pipe Tube Making Machine

{"","Auto Square Duct Production Line 2 Pipe Tube Making Machine is designed for making the production of metal square duct easier and faster. Engineered with hydraulic punching square and notching, it has smooth work flow of coil straightening, beading, punching, notching and shearing. It is made of basic equipment a material frame, a transmission frame, a main machine, and a CNC system. Featured with material saving mode and standard mode, Auto Square Duct Production Line 2 Pipe Tube Making Machine performs with maximum working speed of 13m/min; length tolerance of +0.5mm, and diagonal tolerance of +0.8mm.

Technical Specifications:

| Model No. | Max Coil Width | Thickness Range | Power | Speed | Dimension | Weight | Diagonal Tolerance |

| PM2-1.2x1300 | 1300mm | 0.4-1.2mm | 10 | 0-15m/min | 2x1.8x1.3m 2.5x1.8x1.5m | 3.5ton | +0.5mm |

| PM2-1.2x1550 | 1550mm | 0.4-1.2mm | 11.5 | 0-15m/min | 2x2x1.3m 2.5x2.2x1.5m | 4ton | +0.5mm |

Precision & Automation for Duct Fabrication

Equipped with high-grade, heat-treated steel rollers and an integrated CNC system, the Auto Square Duct Production Line 2 delivers accuracy up to 0.5 mm. The fully automatic operation-featuring servo-controlled punching, hydraulic flying shear, and automatic lubrication-minimizes manual intervention, ensuring high output quality and repeatability for every production run.

User-Friendly Operation with Enhanced Safety

Operators benefit from a HMI touch screen with multilingual support and easy program adjustments via Ethernet or USB. Safety is prioritized using emergency stop features, interlock guards, and audible/visual fault alarms. The IP54-protected electric cabinet and fault monitoring further enhance operational security, making it ideal for demanding industrial environments.

Versatile Application & High Productivity

Designed for producing square and rectangular ducts with widths ranging from 150 to 1250 mm, this machine meets the requirements of HVAC systems, building ductwork, and industrial ventilation pipes. With a production speed of 6-12 m/min and quick changeover features, it supports large-scale fabrication while ensuring consistent performance.

FAQ's of Auto Square Duct Production Line 2 Pipe Tube Making Machine:

Q: How does the Auto Square Duct Production Line 2 improve production efficiency?

A: This machine automates the entire duct forming process-from feeding raw material to punching, forming, and shearing-achieving continuous operation at speeds of 6-12 m/min. Its quick changeover capability, servo-controlled punching, and hydraulic shearing reduce downtime, increasing overall productivity.Q: What materials and thicknesses can be processed with this machine?

A: The line is suitable for carbon steel, galvanized steel, and aluminum sheets with thicknesses from 0.5 mm to 1.2 mm, and material widths between 100 mm and 1250 mm. This makes it ideal for a variety of ductwork fabrication requirements.Q: Where can this duct forming machine be effectively used?

A: Primarily used in manufacturing square and rectangular ducts for HVAC systems, industrial ventilation, and building services, the machine is suitable for factories, workshops, or production plants needing high-volume, precise duct component fabrication.Q: What benefits does the CNC and HMI integration provide?

A: CNC and HMI integration allows for precise programming, data upload, and easy program changes. Operators can quickly adjust settings, monitor production, and access multi-language support for global usability, ensuring efficient and accurate operations.Q: How is operator safety ensured during machine operation?

A: The system includes key safety features such as emergency stop buttons, interlock guards, fault alarms, and an IP54-rated electric cabinet. These safeguards protect operators from mechanical and electrical hazards during operation and maintenance.Q: What is the process for changing duct sizes or punch patterns?

A: Switching duct sizes or punch patterns is streamlined by the machine's quick-change system, servo feeder, and interchangeable dies. The PLC touch screen interface guides operators through the changeover procedure, minimizing downtime and complexity.Q: What are the long-term benefits of using this machine for duct production?

A: The robust construction, high automation, precision forming, and integrated lubrication system contribute to reduced labor costs, consistent quality, and higher throughput. These factors ensure long-term reliability and cost-effectiveness for manufacturers.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in HVAC Duct Machine Category

Auto Duct Pipe Production Line 3 Duct Pipe Making Line III

Price Range 600.00 - 6000.00 USD ($) / Unit

Minimum Order Quantity : 1 , , Unit

Weight (kg) : Approx. 3500 kg

Dimension (L*W*H) : 12000 x 2200 x 1500 mm

Model No : Line III

Drive : AC Motor Drive

6 mm Automatic Angle Steel Punching And Cutting Machine With Flange Punching Line

Price Range 600.00 - 6000.00 USD ($) / Unit

Minimum Order Quantity : 1 Unit

Weight (kg) : 9500 kg

Dimension (L*W*H) : 8500 mm x 2200 mm x 1800 mm

Model No : ASPC6FPL

Drive : Servo & Hydraulic

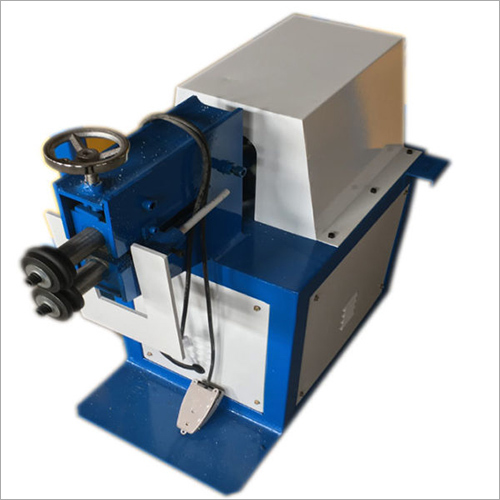

Groove Rotary And Duct Reviting Machine

Price Range 600.00 - 6000.00 USD ($) / Unit

Minimum Order Quantity : 1 , , Unit

Weight (kg) : 180 kg

Dimension (L*W*H) : 1200 mm x 650 mm x 1000 mm

Model No : GRM100

Drive : Gear Drive

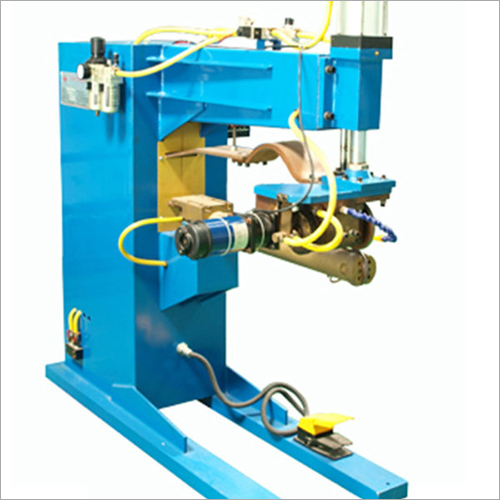

Air Duct Pipe Seam Welding Machine Duct Pipe Seam Welder Machine

Price Range 600.00 - 6000.00 USD ($) / Unit

Minimum Order Quantity : 1 Unit

Weight (kg) : 1200 kg

Dimension (L*W*H) : 3200mm 1000mm 1800mm

Model No : ADS1600

Drive : Chain Drive

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry