Delem CNC Synchronized Press Brake Bending Machine

Delem CNC Synchronized Press Brake Bending Machine Specification

- Motor Speed

- 1440 rpm

- Bending Strength

- Up to 200 Ton

- Bending Speed

- 8 mm/s to 12 mm/s (approx.)

- Dimension (L*W*H)

- 3500mm x 1800mm x 2500mm

- Color

- White & Blue

- Automation

- CNC Controlled

- Usage

- Sheet Metal Bending / Metal Forming

- Capacity

- 100-200 Tons

- Weight

- 6000 kg (approx.)

- Voltage

- 380V / 415V

- Condition

- NEW

- Place of Origin

- China

- Bend Radius

- Minimum 1 mm (depending on tooling)

- Bending Angle

- 0 - 180 adjustable

- Machine Type

- CNC Synchronized

- Phase

- Three Phase

- Output

- High Precision Bending

- Production Capacity

- 8-12 Cycles/min

- Power

- Electric

- Raw Material

- Sheet Metal / Mild Steel / Stainless Steel

- Product Type

- Press Brake Bending Machine

- Repetitive Positioning Accuracy

- 0.03 mm

- Throat Depth

- 400 mm

- Safety Features

- Laser Safety Curtain, Emergency Stop

- Control System

- Delem DA Series CNC Controller

- Noise Level

- 75 dB

- Working Table Height

- 860 mm

- Programmable Memory

- 100 Programs / 25 Bends per Program

- Frame Structure

- Welded, Stress Relieved Steel

- Tool Clamping

- Quick Release Clamping System

- Hydraulic System

- Imported Integrated Hydraulic System

- Back Gauge Stroke

- 600 mm (Maximum)

- Main Pump Brand

- Bosch Rexroth / Siemens

- Operation Interface

- Color Touch Screen

- Oil Tank Capacity

- 370 Liters

- Axis Control

- Y1, Y2, X, R Axes (Full Synchronized)

Delem CNC Synchronized Press Brake Bending Machine Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 1 Unit Per Day

- Delivery Time

- 13 Days

About Delem CNC Synchronized Press Brake Bending Machine

| Model(Primapress ) | 1560 | 2580 | 32110 | 32135 | 32175 | 40175 | 32220 | ||

| Bending force | KN | 600 | 800 | 1100 | 1350 | 1750 | 1750 | 2200 | |

| Bending Length | mm | 1500 | 2500 | 3200 | 3200 | 3200 | 4200 | 3200 | |

| Between Columns | mm | 1100 | 2060 | 2700 | 2700 | 2700 | 3700 | 2700 | |

| Daylight | mm | 405 | 405 | 430 | 430 | 430 | 430 | 430 | |

| Slide Stroke | mm | 200 | 200 | 200 | 200 | 200 | 200 | 200 | |

| Throat Depth | mm | 370 | 400 | 400 | 400 | 400 | 400 | 400 | |

| Bolster Width | mm | 80 | 80 | 100 | 100 | 100 | 100 | 140 | |

| Down Speed | mm/min | 200 | 200 | 180 | 180 | 160 | 160 | 160 | |

| Pressing Speed | mm/min | 8 | 8 | 10 | 10 | 10 | 10 | 10 | |

| Return Speed | mm/min | 180 | 180 | 150 | 150 | 150 | 150 | 140 | |

| Back Gauge Stroke | mm | 500 | 600 | 800 | 800 | 800 | 800 | 800 | |

| Outline Size | L | mm | 1825 | 2825 | 3500 | 3550 | 3500 | 4500 | 3500 |

| W | mm | 1650 | 1650 | 1650 | 1650 | 1650 | 1650 | 1730 | |

| H | mm | 2300 | 2350 | 2650 | 2700 | 2700 | 2750 | 2900 | |

| Weight | kg | 4600 | 5600 | 8000 | 9500 | 10000 | 12000 | 13200 | |

Advanced CNC Control for Superior Precision

Equipped with the Delem DA Series CNC Controller, this press brake offers seamless synchronization of all major axes. The color touch screen allows operators to program up to 100 bending programs, with 25 bends per program, ensuring flexible and precise production. The automation enhances productivity without sacrificing accuracy.

Robust Construction for Lasting Durability

The main frame structure is welded and stress relieved, providing exceptional stability and longevity. Top-brand hydraulic components from Bosch Rexroth or Siemens, combined with an imported integrated hydraulic system, ensure smooth, consistent operations for heavy-duty metal forming projects.

Safety and Efficiency Combined

Operator safety is enhanced by a laser safety curtain and emergency stop button, minimizing risks during operation. A quick-release clamping system simplifies tool changes, helping to speed up workflow and reducing machine downtime for continuous, efficient production.

FAQs of Delem CNC Synchronized Press Brake Bending Machine:

Q: How does the Delem CNC Synchronized Press Brake achieve high precision bending?

A: This machine utilizes the Delem DA Series CNC Controller for full synchronization of Y1, Y2, X, and R axes, together with an advanced positioning system ensuring repeatability within 0.03 mm. The robust frame and imported hydraulic system provide exceptional bending accuracy for every cycle.Q: What materials can be processed using this CNC press brake?

A: The machine is designed for bending sheet metal, mild steel, and stainless steel. Its high bending strength (up to 200 tons) and adjustable bending angle (0180) make it versatile for a wide range of metal forming applications.Q: When is the quick-release clamping system beneficial for operators?

A: The quick-release clamping system significantly reduces tool change times, making it especially beneficial during production runs that require frequent die or tool swaps. This boosts overall efficiency and minimizes machine downtime.Q: Where is this CNC press brake typically used?

A: This press brake is widely used in metal fabrication workshops, manufacturing plants, and industrial production lines where precise sheet metal bending and forming are required. Its high reliability makes it suitable for both large-scale and custom manufacturing environments.Q: What safety features are integrated into the machines design?

A: Operator safety is prioritized with a laser safety curtain and an emergency stop button. These features protect users by quickly stopping machine operations in case of potential hazards, ensuring a safe working environment.Q: How can users program and store bending operations?

A: Operators can easily create and store up to 100 bending programs, with up to 25 bends per program, using the color touch screen operation interface. This allows for quick recall and repeatability of production processes, enhancing productivity.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Bending Machine Category

CNC Full Auto Numerical Control Single Head Pipe Tube Automatic Bending Machine

Price Range 600.00 - 6000.00 USD ($) / Unit

Minimum Order Quantity : 1 Unit

Bending Strength : High

Motor Speed : 1400 rpm

Machine Type : CNC Full Auto Numerical Control Single Head

Color : Blue & Yellow

50 Ton Hydraulic CNC Press Brake Bending Machine

Price Range 600.00 - 6000.00 USD ($) / Unit

Minimum Order Quantity : 1 , , Unit

Bending Strength : 50 Ton

Motor Speed : 1440 RPM

Machine Type : CNC Sheet Metal Bending Machine

Color : Blue & White

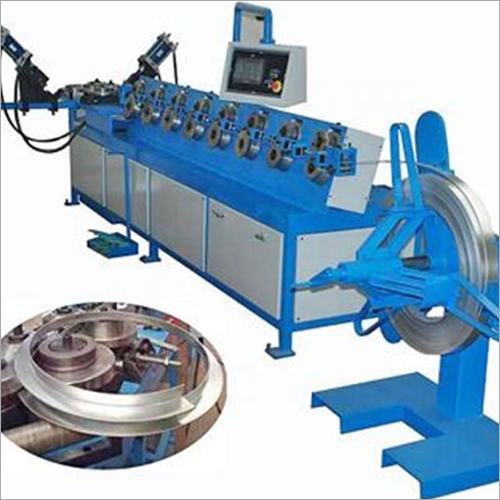

CNC Round Iron Flange Forming Machine

Price Range 600.00 - 6000.00 USD ($) / Unit

Minimum Order Quantity : 1 , , Unit

Bending Strength : Up to 300 MPa

Motor Speed : 1440 rpm

Machine Type : Flange Forming Machine

Color : Blue & Silver

3-8mm Stainless Steel 3d Cnc Wire Bending Machine 3d Wire Bending Machine

Price Range 600.00 - 6000.00 USD ($) / Unit

Minimum Order Quantity : 1 Unit

Bending Strength : Up to 8 mm Stainless Steel Wire

Motor Speed : 1500 rpm

Machine Type : Automatic Wire Bending Machine

Color : Standard / Custom as per order

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry