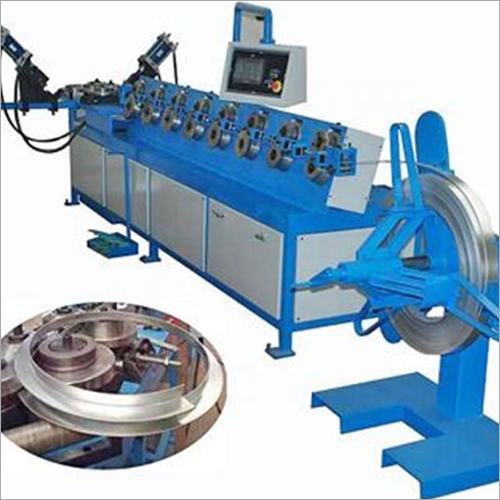

CNC Round Iron Flange Forming Machine

CNC Round Iron Flange Forming Machine Specification

- Condition

- NEW

- Phase

- Three Phase

- Dimension (L*W*H)

- 2600 x 1100 x 1400 mm

- Raw Material

- Iron

- Capacity

- Up to 16 mm thickness

- Power

- 7.5 kW

- Motor Speed

- 1440 rpm

- Color

- Blue & Silver

- Product Type

- CNC Round Iron Flange Forming Machine

- Automation

- CNC Automatic

- Bend Radius

- Min. 50 mm

- Machine Type

- Flange Forming Machine

- Bending Angle

- 0~90 adjustable

- Usage

- Industrial Flange Making

- Production Capacity

- 350-500 pieces/day

- Place of Origin

- China

- Output

- High Efficiency

- Weight

- 1200 kg

- Bending Strength

- Up to 300 MPa

- Voltage

- 380V / 415V

- Bending Speed

- 5-10 m/min

- Drive Type

- Electric

- Lubrication System

- Automatic

- Control System

- PLC Touch Screen

- Roller Material

- Alloy Steel

- Working Pressure

- Adjustable via control

- Safety Features

- Emergency stop, sensor protected

- Noise Level

- 75 dB

- Flange Width Range

- 10-200 mm

- Working Mode

- Horizontal

- Operation Language

- English/Chinese selectable

- Surface Treatment

- Powder Coated

- Material Thickness Range

- 1.2-16 mm

CNC Round Iron Flange Forming Machine Trade Information

- Minimum Order Quantity

- 1 , , Unit

- Supply Ability

- 1 , , Unit Per Day

- Delivery Time

- 13 Days

About CNC Round Iron Flange Forming Machine

{"","CNC Round Iron Flange Forming Machine, also known as CNC angle steel round form machine, is designed to use in metalworking industry for bending pipes, profile, etc. with high efficiency and accuracy. It is easy to operate, robust construction, durable, and rust proof, as it is precision designed and developed expert professionals using top-grade steel contact parts, user-friendly operating unit, and advanced technologies as per international quality standards. Besides, CNC Round Iron Flange Forming Machine is available in varied powers, sizes, models and specifications at negotiable prices.

Technical Specifications:

- Thickness: 2-5mm

- Min Diameter Range: 200mm

- Angle iron specification: 30x20, 30x30, and 30x40

- Discharge rack: 850x850x1250

Advanced CNC Automation for Flange Forming

With fully automatic, CNC-controlled operations and a user-friendly PLC touch screen, this machine transforms raw iron into precision flanges. The horizontal working mode and programmable settings streamline the bending process, ensuring outputs meet exact requirements for width, angle, and thickness every cycle.

Robust Construction and Flexible Capabilities

Built with alloy steel rollers and powder-coated surfaces, the machine handles iron up to 16 mm thickness and flanges from 10-200 mm wide. The automatic lubrication system minimizes maintenance, while sensor-based safety features and emergency stop functions safeguard operators during high-efficiency production.

High Productivity and Versatile Application

Producing up to 500 flanges daily, this machine suits industrial-scale operations seeking reliable, repeatable results. Adjustable bending parameters accommodate diverse flange specifications, making it a vital asset for manufacturers, distributors, traders, and exporters dealing in iron flange products.

FAQ's of CNC Round Iron Flange Forming Machine:

Q: How does the CNC Round Iron Flange Forming Machine operate?

A: The machine is operated through a PLC touch screen interface, allowing users to set parameters for flange dimensions, thickness, and bending angles. It uses an electric drive for smooth, automated forming, with all functions centrally controlled and continuously monitored for efficiency and safety.Q: What materials and thickness ranges can the machine process?

A: This machine is designed for iron, with a material thickness range of 1.2-16 mm. It delivers precise forming on a variety of flange widths (10-200 mm), all processed by high-strength alloy steel rollers.Q: When should the working pressure be adjusted?

A: Adjust the working pressure via the control system depending on both the material thickness and desired flange specifications. Higher pressure may be needed for thicker materials or larger bends to ensure consistent and accurate forming results.Q: Where is this machine commonly used?

A: It is primarily used in industrial manufacturing facilities, particularly by manufacturers, suppliers, and exporters specializing in iron flange production for pipelines, mechanical applications, and fittings, both domestically and internationally.Q: What is the process of forming a flange using this machine?

A: Operators load iron material into the machine, input the required flange parameters on the PLC touch screen, and initiate the process. The machine automatically bends the material horizontally, with adjustable angles (0-90) and speeds (5-10 m/min), producing high-quality flanges with every cycle.Q: How does the machine ensure user safety during operation?

A: It is equipped with an emergency stop button and sensor-protected safety systems, automatically halting operation in case of anomaly. The low noise level (75 dB) and powder-coated exterior further enhance safe and comfortable use.Q: What are the main benefits of using this flange forming machine?

A: This machine maximizes productivity (up to 500 pieces/day), enhances bending accuracy, supports heavy-duty material, and minimizes labor with its CNC automation. It also reduces maintenance needs with an automatic lubrication system, increasing reliability and operational efficiency.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Bending Machine Category

DA66T aluminum iron plate 8+1 axis CNC Servo Hydraulic Press Brake Bending Machine

Price Range 600.00 - 6000.00 USD ($) / Unit

Minimum Order Quantity : 1 Unit

Power : Servo Hydraulic

Color : Blue and White (as per image)

Motor Speed : Variable (Inverter Controlled, up to 1500 rpm)

Bending Strength : Up to 200 Tons (customizable)

6 axis +1 axis CNC Servo Hydraulic Press Brake Machine

Price Range 600.00 - 6000.00 USD ($) / Unit

Minimum Order Quantity : 1 , , Unit

Power : Servo Hydraulic

Color : White & Blue

Motor Speed : Variable, up to 1500 RPM

Bending Strength : Up to 300 tons

Auto 2 Rolls Plate Bending Machine

Price Range 600.00 - 6000.00 USD ($) / Unit

Minimum Order Quantity : 1 , , Unit

Power : Electric

Color : Blue & White

Motor Speed : 1440 RPM

Bending Strength : Up to 260 MPa

CNC Full Auto Numerical Control Single Head Pipe Tube Automatic Bending Machine

Price Range 600.00 - 6000.00 USD ($) / Unit

Minimum Order Quantity : 1 Unit

Power : 7.5 kW

Color : Blue & Yellow

Motor Speed : 1400 rpm

Bending Strength : High

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry