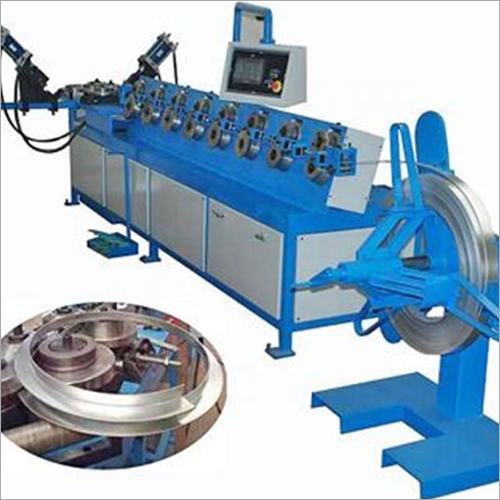

CNC Full Auto Numerical Control Single Head Pipe Tube Automatic Bending Machine

CNC Full Auto Numerical Control Single Head Pipe Tube Automatic Bending Machine Specification

- Bend Radius

- Customized (Min 1.5D of tube diameter)

- Motor Speed

- 1400 rpm

- Production Capacity

- 150-200 pieces/hour

- Place of Origin

- China

- Dimension (L*W*H)

- 400011001500 mm

- Raw Material

- Metal (Steel, Stainless Steel, Copper, etc.)

- Bending Angle

- 0 to 190

- Power

- 7.5 kW

- Machine Type

- CNC Full Auto Numerical Control Single Head

- Color

- Blue & Yellow

- Phase

- Three Phase

- Condition

- NEW

- Capacity

- Up to 60 mm OD pipe

- Weight

- 2400 kg

- Bending Speed

- Max 12 seconds per bend

- Usage

- Pipe and tube bending

- Voltage

- 380V

- Automation

- Fully Automatic

- Output

- High Precision Bent Pipes

- Bending Strength

- High

- Product Type

- Pipe Tube Automatic Bending Machine

- Hydraulic System Pressure

- 16 Mpa

- Tooling Changeover Time

- Typically less than 15 minutes

- Mandrel Adjustment

- Motorized

- Material Feeding

- Automatic

- Display

- LCD color display

- Data Storage

- Can store up to 1000 bending programs

- Safety Features

- Emergency stop, safety guards, overload protection

- Software Compatibility

- Supports standard DXF and IGES file imports

- Control System

- Advanced CNC with touchscreen interface

- Clamping Method

- Hydraulic

- Noise Level

- 75 dB

- Lubrication System

- Central automatic lubrication

- Servo Drive

- Included for precision positioning

- Working Temperature Range

- 0C to 45C

CNC Full Auto Numerical Control Single Head Pipe Tube Automatic Bending Machine Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 1 Unit Per Day

- Delivery Time

- 13 Days

About CNC Full Auto Numerical Control Single Head Pipe Tube Automatic Bending Machine

Extensively Used Across Multiple Industries

The CNC Full Auto Numerical Control Single Head Pipe Tube Automatic Bending Machine is widely used by distributors, exporters, manufacturers, suppliers, and traders in China and globally. It excels in automobile manufacturing, shipbuilding, furniture, HVAC, and construction plants owing to its ability to bend various metals with high precision. Key features such as servo drive positioning, motorized mandrel adjustment, advanced safety, and quick tool changeover make it an indispensable asset in any industrial environment.

FOB Port, Sample Policy, Payment Terms: Order and Supply Information

This CNC machine is supplied directly from China, with flexible FOB port arrangements for international trading. Samples are available as per established sample policy, ensuring satisfaction prior to bulk orders. Payment terms are negotiable to accommodate both domestic market requirements and exporters. Order completion is handled with efficiency, facilitating prompt supply chains and integrated logistics for swift domestic and global delivery. Experience seamless acquisition-from inquiry to installation.

FAQ's of CNC Full Auto Numerical Control Single Head Pipe Tube Automatic Bending Machine:

Q: How does the CNC Full Auto Numerical Control Single Head Pipe Tube Automatic Bending Machine ensure precision in bending?

A: The machine utilizes a servo drive for accurate positioning and features an advanced CNC control system with touchscreen interface, ensuring high precision during each bend.Q: What type of materials can I use with this pipe and tube bending machine?

A: It is engineered to handle various metals, such as steel, stainless steel, and copper, making it suitable for a range of industrial applications.Q: Where is the machine manufactured and supplied from?

A: This machine is manufactured in China and is available for supply to both domestic and international markets through reputable distributors, exporters, and suppliers.Q: What are the benefits of the automatic feeding and central lubrication system?

A: The automatic material feeding and centralized lubrication system boost productivity, reduce operator workload, and extend machine lifespan by ensuring smooth, low-maintenance operation.Q: How fast can the tooling be changed over for different bending requirements?

A: Tooling changeover typically takes less than 15 minutes, which minimizes downtime and increases operational efficiency during manufacturing processes.Q: What is the typical production capacity and speed of the machine?

A: The machine can bend up to 150-200 pieces per hour, with a maximum bending speed of 12 seconds per bend, offering high output for demanding production environments.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Bending Machine Category

CNC Round Iron Flange Forming Machine

Price Range 600.00 - 6000.00 USD ($) / Unit

Minimum Order Quantity : 1 , , Unit

Color : Blue & Silver

Machine Type : Flange Forming Machine

Bending Strength : Up to 300 MPa

Power : 7.5 kW

50 Ton Hydraulic CNC Press Brake Bending Machine

Price Range 600.00 - 6000.00 USD ($) / Unit

Minimum Order Quantity : 1 , , Unit

Color : Blue & White

Machine Type : CNC Sheet Metal Bending Machine

Bending Strength : 50 Ton

Power : 5.5 kW

CNC Flexible Bending Cells-Gantry Robot + CNC Press Brake Machine

Minimum Order Quantity : 1 Unit

Color : Blue/White (as per image)

Machine Type : Press Brake + Gantry Robot

Bending Strength : Up to 200 Ton

Power : Variable, depending on model (typically 515 kW)

Delem CNC Synchronized Press Brake Bending Machine

Price Range 600.00 - 6000.00 USD ($) / Unit

Minimum Order Quantity : 1 Unit

Color : White & Blue

Machine Type : CNC Synchronized

Bending Strength : Up to 200 Ton

Power : Electric

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry